The food industry is complex with many steps involved in harvesting the raw ingredients, processing them, and selling them in stores. Scales are used in virtually every step from farm to table, serving a variety of purposes for the many applications in the food chain. In this post, we'll cover some important features of scales used during food production and processing.

If you're interested in reading more about catering and kitchen scales, please take a look at a recent blog post covering that topic. We also have a post on retail scales that provides information on scales in grocery stores and delis.

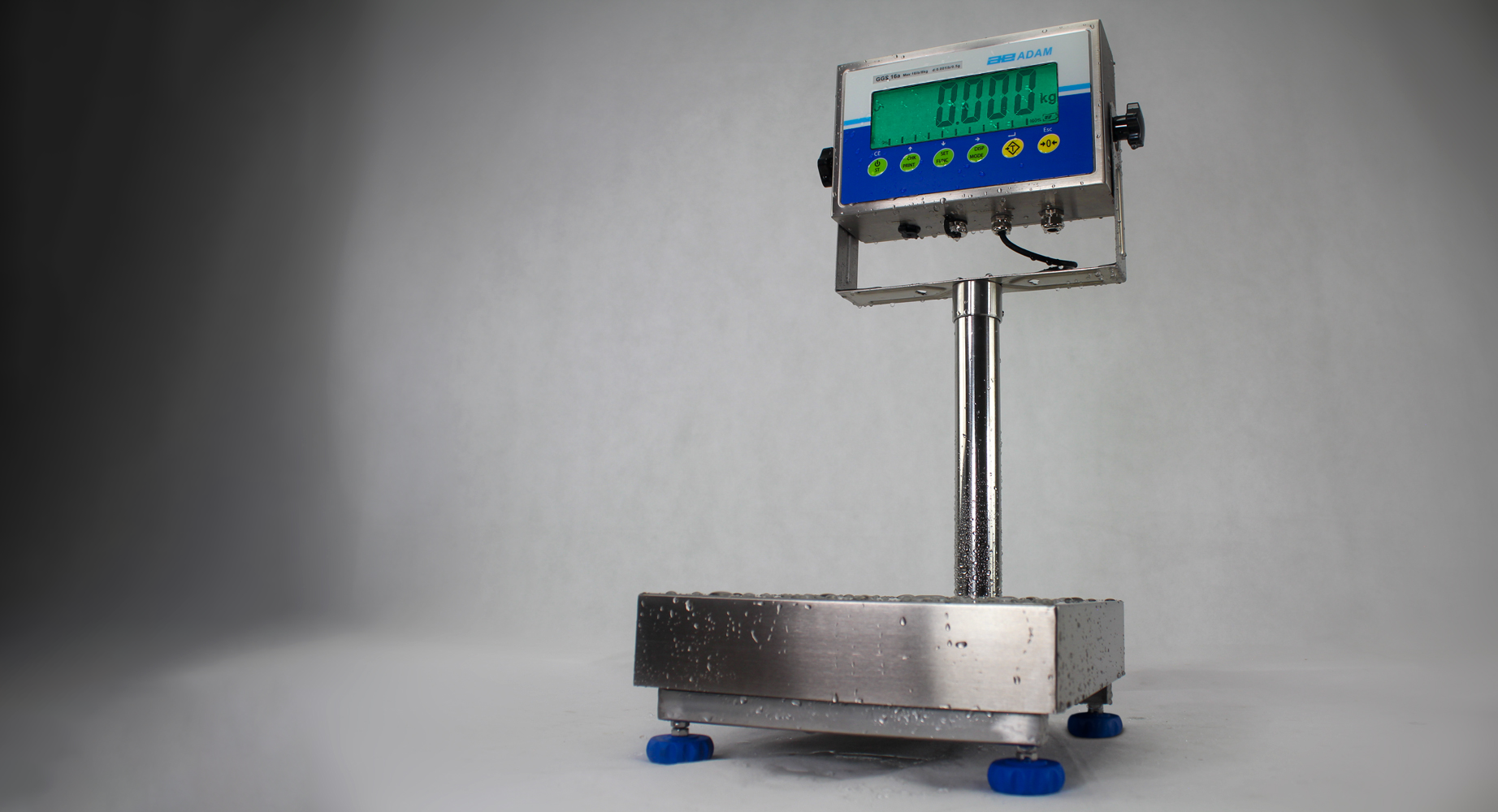

It's essential for scales used in food processing to have an IP rating. Adam's washdown scales have a minimum of an IP67 rating, which makes them resistant to dirt, dust, spills, moisture and water. They can be can be safely washed and hosed down so they are easy to clean, which is paramount in the food industry. Impeccable hygiene must be maintained for safety and to avoid cross contamination. The food must remain safe to eat at every stage of the process.

RS-232 interfaces can be very useful on scales; they can connect to computers and printers to ensure detailed records are kept, and users can use software to analyze the data (for example, to reduce food waste or to check the yield of crop compared to last year). They can also help compile and graph data for quality testing, traceability, compliance and inventory management applications.

The tare feature is useful for food that is weighed in a container, since you don't want to include the weight of the bag or box when you sell food. Digital scales have a tare button, and some scales have preset tare to make repetitive weighings quicker and easier.

Weighing scales used in food production

The beginning of the food cycle includes farming and food materials being checked and quantified before processing. Fishermen, for example, need to know how heavy the fish they catch are, the yield of the fishing trip and how it compares to similar ones. Most food is sold by weight, so it's important to track. Customers and producers want to make sure they pay and get paid for the correct amount of food. An efficient weighing process also helps to reduce food waste, which is a colossal problem for the food industry. Usually, food at this stage is raw or has had very little processing, and is weighed in bulk. High capacity scales like the PT-S are frequently used at this stage to weigh great quantities of food.

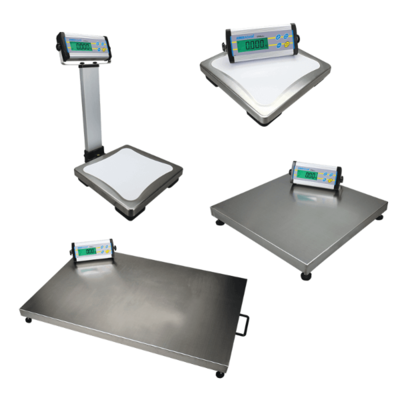

Using weighing scales for food processing

The food is weighed to put in packages, or to mix with other substances so it will last longer, or as part of a full recipe (for example, a company's brand of beverages might have a few different fruits in them). Accuracy is key, as consumers expect the same, consistent taste as before. It's also important to make sure the right amount of food goes into the package. The scales used at this stage can have a lower capacity, but higher readability, and features such as become quite useful during the packaging stage. Other useful features can include batching, formulation, counting and accumulation. or even can be used during quality testing to ensure small samples are high quality.

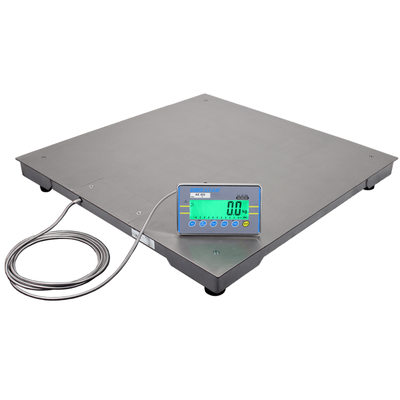

Weighing scales for shipping & receiving operations

From full containers or crates, to individual packages, scales are used for quality control and to ensure the right amount of food is sent to the right places. Shops want to make sure they receive the right amount of food. It's important that containers in trucks or ships don't go over capacity. Platform scales can be paired with indicators that bring accuracy and useful features to high capacity industrial durability.

There are different capacities and readabilities at every stage, but these are the features that are necessary throughout the industry. Thank you for reading, and as always, don't hesitate to contact us if you have questions, and follow us on social media for Adam news and more blog posts.