The words precision and balance almost seem like a tautology; after all, you expect any balance you buy to be precise. In the weighing industry, precision balances are a specific category of weighing instruments that refer to the level of resolution or readability they offer. In this post, we’ll explore the functions that make precision balances different from other balances, their definition, their applications, and more.

What is a precision balance?

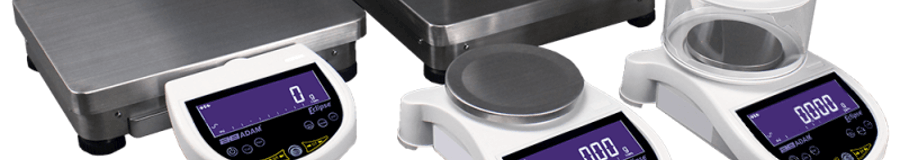

In the weighing industry, we define precision balances as “a balance used to weigh quantities to a very precise number, usually up to one milligram”. They’re sometimes referred to as “top loading balances”. Precision balances are available in a wide range of capacities, from several hundred grams up to kilograms. They’re not as precise as analytical balances, but more precise than the average bench or compact scale. Also, precision balances have a higher capacity than analytical balances, but a lower readability.

Adam Equipment precision balances have a readability of 0.001g at the most.

What are some common applications of precision balances?

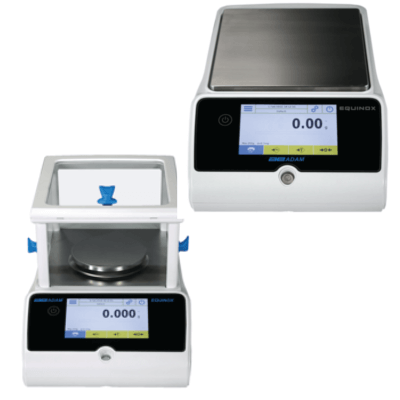

Precision balances have many uses throughout various industries. Some balances, like our large pan Luna, Solis or Equinox balances, have a high enough capacity and level of sturdiness necessary to test materials like concrete at construction sites with the readability necessary to get scientific results. They can be transported for use in field work or used in other outdoor settings, as well as being used on a lab workstation. Precision balances are used in various laboratories and chemistry applications, and are a common sight in labs for use in anything from advanced physics classes to biology research.

Precision balances are often used in the medical and pharmaceutical fields, where their higher readability and capacity is helpful for weighing test samples, equipment and chemicals, including blood packs medicines. Production is another industry where precision scales are used frequently, as are industrial and manufacturing operations since they can precisely calculate the weight of materials used in lubricants and oils. They can also be used in the jewelry industry for weighing gold, gems and other precious metals and stones. Trade approved precision balances such as Adam Equipment's Highland are often used to create cosmetic products since they are precise enough to weigh ingredients in tiny amounts and have the necessary certifications for selling products by weight.

Typical functions of precision balances

Precision balances tend to have more features than bench scales or compact balances. Many of them have below-balance weighing for density measurement. All our precision balances have RS-232 interfaces for communicating data to computers and printers. They often have multiple weighing applications as well, such as percentage weighing, dynamic weighing, parts counting and more. Overload protection ensures the balance’s durability.

Some functions depend on the models. Some precision balances are compact and can be stacked for use in small labs or classrooms. Others are sturdy and have a large pan for field use, and some, like our Equinox series, have the readability necessary for research in labs. Our Core and Highland ranges are also equipped with our trademarked Shockprotect and Handical features.

How to choose the best precision balance for your needs

As always, consider your application when you start your search. Precision balances are varied category of weighing equipment, and our Luna, Solis and Equinox balances have many different body types, capacities and readabilities available. If you need a balance for material testing at construction sites or heavy industrial application, consider a sturdier scale with a high capacity. If you only weigh small samples in classrooms or labs, a scale with higher readability and a more compact design will suffice.